How to apply multi-forging die forging method

作者:admin 来源:本站 发布时间:2019-11-06 06:45:27 浏览量:

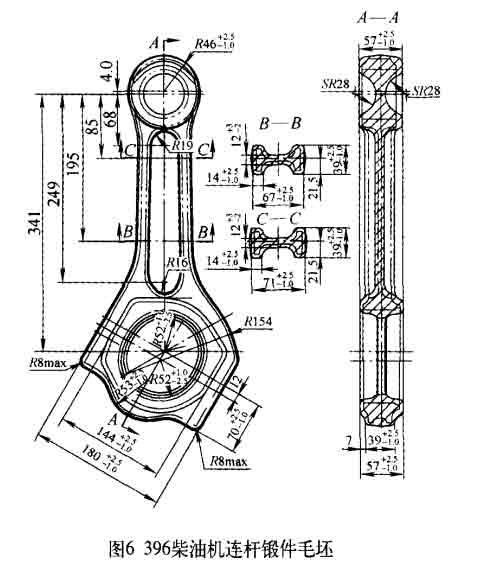

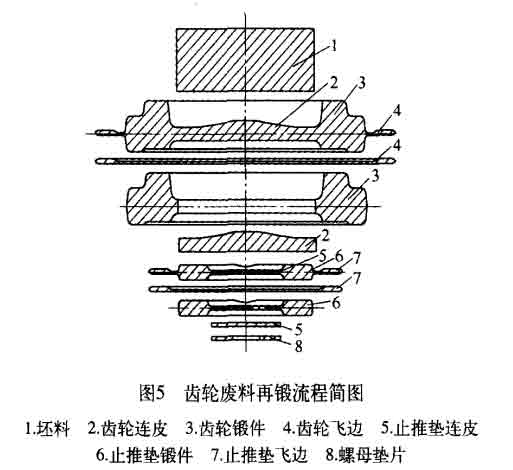

(1) One-die multi-forging one-die multi-forging can improve the function, economy and forging efficiency of the forging die, but it also increases the forging die size and equipment tonnage. When the forging die size and equipment tonnage are insufficient, it is extremely easy. Lead to forming difficulties and low forging efficiency. The speed regulating hammer is a small die forging piece with a single piece weight <0.2kg (see Figure 1). The parts are made of alloy steel 12CrNi3A~ high temperature alloy GH4080A. The die forging method has obvious differences. The forging condition of 12CrNi3A steel die forging is less, the die forging process is better, and it is suitable for one die forging, forging die forging, continuous forging and multi-piece forging. In the case of one-die multi-forging, one forging or three forging can be realized; or when forging and forging, and then forging for one die, one forging or one forging can be realized. High temperature alloy GH4080A die forging has many constraints, such as low plasticity, large deformation resistance, high adhesion, strong sensitivity to heating rate, narrow forging temperature range, strict forging temperature requirements, low thermal conductivity, corresponding variable rate Strong sensitivity to stress state, obvious cold work hardening tendency, high recrystallization temperature and slow speed, wide range of critical deformation, and no unfavorable factors such as homogeneous transformation during heating and die forging. It is not suitable for one-piece multi-forging, turning head forging, continuous multi-forging, composite die forging and multi-piece forging, etc. It is only suitable for one material and one forging.

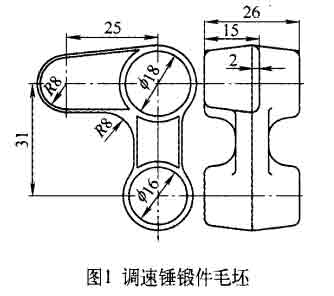

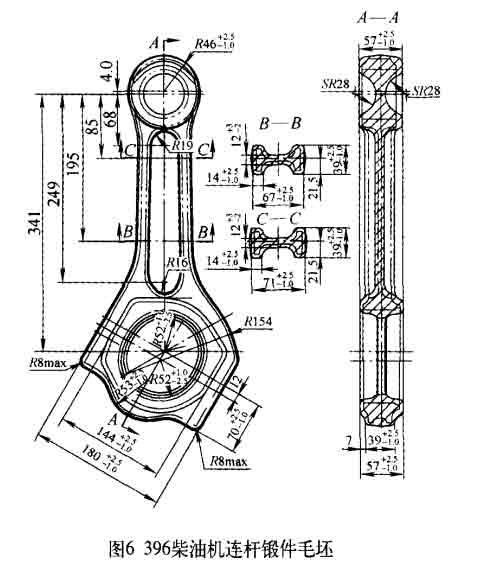

(2) Continuous multi-forging refers to the stepwise die forging one piece of forging piece on the same set of forging die, then cutting and forging the forging piece from the blank by cutting the die, and then forging and then cutting off to obtain ≥ A die forging method for 3 forgings. Continuous multi-forging can fully utilize the clamp head to save raw materials, but the final formed forgings have lower temperature and are not easy to cut, which will affect the forging quality, forging efficiency and forging die life. The process of continuous multi-forging of the pin forgings (see Fig. 2) is as follows: pulling one roll, one forging, one forging, one for cutting, one for long, one for rolling, one forging, one for cutting, one for long, one for rolling, one forging, that is, first The first section of the blank is sequentially lengthened, rolled and finally forged, and then the formed first forging is cut on the cutting die; then the second section of the blank is sequentially lengthened, rolled and finally forged, and then The formed second forging is cut on the cutting die; finally, the third segment of the remaining blank is sequentially elongated, rolled and finally forged. Continuous multi-forging of the pin can realize three-forging of one material, which can minimize the volume of the clamping head.

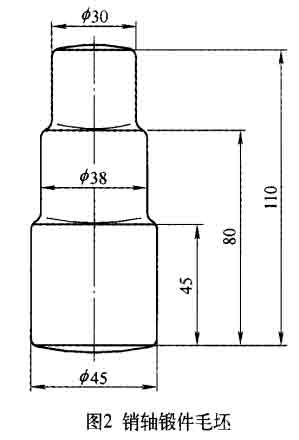

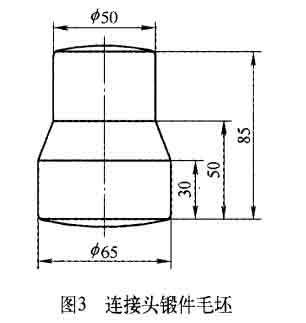

(3) Turning die forging refers to forging a blank in the same set of forging dies to form ≥1 forgings (or forming a part of the blanks), then forging the forgings before and after forging and forming ≥1 for another forging ( Or another part of the blank is formed to obtain a forging forming method of ≥ 2 (or ≥ 1) forgings. The head swaging can fully utilize the jaws to save raw materials, and the forging efficiency is high. However, the forging billet has a low temperature after turning the head, which has a certain influence on the service life of the forging die and the quality of the forging. The joint forging of the joint head (see Fig. 3) is as follows: the length of the final forging and the final forging, that is, the intermediate part of the blank is first lengthened, and then the half of the blank is forged into one forging, and then The other half of the blank is forged into another forging by clamping the forging before and after the forging with a pair of pliers to realize one forging and two forging. The joint head forging can achieve the effects of small clampless chuck, high forging efficiency, high service life of forging die and good consistency of forgings.

(4) Composite die forging refers to a die forging method for obtaining a forging of different shapes, sizes and performances of ≥ 2 pieces by one-time composite die forging on a set of forging dies. Composite die forging maximizes the material utilization of forgings and features “minimum input, maximum recycling, maximum resource and energy use, and minimal environmental change”. However, the shape and size of the composite forging of large forgings and small forgings are difficult to match. The process of gear composite die forging (see Fig. 4) is: composite forging of blank 1 into large gear forgings 2, pinion forgings 4 and nut washer forgings 5. The gear composite die forging realizes a three-forging of the material, and the 3R operation principle of “reduction, reuse and recycling” of the circular economy from input to output can reduce the consumption of raw materials by 12%.

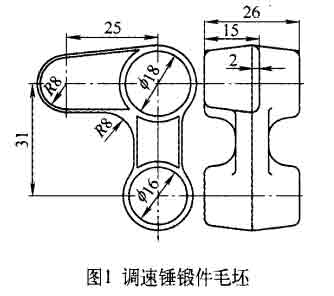

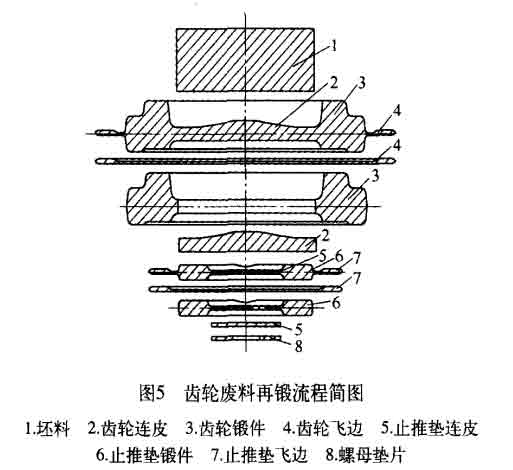

(5) Re-forging of scraps refers to the use of punching or nipples and other pieces of scrap forging and forging after ≥1 forgings to obtain ≥1 pieces of small forgings of different shapes and sizes A die forging forming method. Re-forging of scraps can maximize the utilization of gear forgings and is more refined, cleaner and more economical. However, re-forging waste is more difficult to match the material grade, shape and size or volume of the new forging. The process of gear forging and forging (see Fig. 5) is as follows: firstly forging the blank 1 into a gear forging 3 and a large gear punching and joining the skin 2, and then using the punching and peeling 2 scrap forging forming the push pad forging 6 and finally The punched skin 5 of the thrust pad forging 6 is punched or machined as a nut spacer 8. Re-forging of gear scraps realizes the recycling of three forgings and large gear punching and peeling waste materials, which can reduce raw material consumption by 12%.

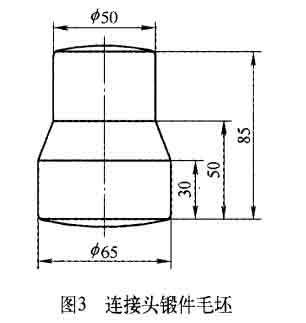

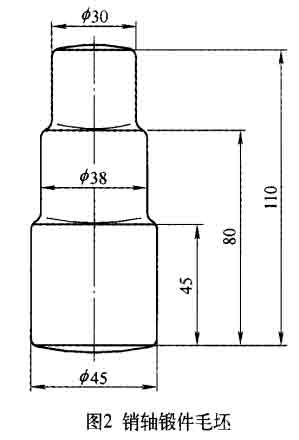

(6) Multi-piece forging refers to a die forging method in which ≥ 2 pieces of forgings are combined into one die forging by one piece of blank, and then cut and separated by forging, sawing or wire cutting. Multiple pieces of forging can reduce the variety of forgings and forgings. Different forgings have the same material grade and batch, and the same or similar mechanical properties. However, when the total qualified rate of each forging obtained after forging and machining is different, the final number of each forging is difficult to achieve one-to-one correspondence, and the size of the forging die may be increased, and the die forging may be increased. Equipment tonnage and affecting die forging efficiency. The 396 diesel engine connecting rod forging is a two-piece integral forging and connecting rod cover (see Figure 6). The sequential forging method and the anti-deformation die forging principle are used to optimize the forging die design, which effectively improves the die forging process. The number of forging processes is reduced, the forging energy consumption is reduced, the mechanical properties and quality consistency of the forgings are ensured, and labor-saving and time-saving forming are achieved (the die forging effect on the 3t die forging hammer with relatively low impact energy exceeds Die forging effect on 5t die forging hammer).